Current issue

Online First

Archive

Instructions for Authors

Guide for Authors

Peer Review Policy

Research Ethics Policy

Ghostwriting and Guest Authorship

Copyright

Open Access Policy

Plagiarism

About the Journal

Aim and Scope

Scientific Board

Publisher

Editorial Board

Indexing in Databases

Personal Data Protection

Repository Policy

Contact

ORIGINAL PAPER

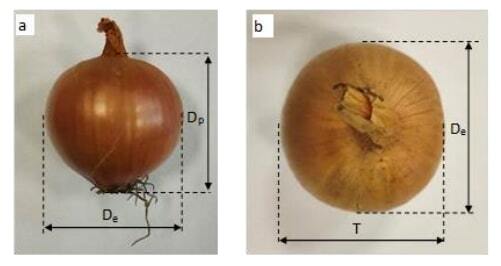

Analysis of the Waste Generated during the Cutting Process in Onion Topping and Tailing

1

Poznań Institute of Technology, Łukasiewicz Research Network, Poland

2

Faculty of Mechanical Engineering, Poznań University of Technology, Poland

3

Faculty of Civil and Transport Engineering, Poznań University of Technology, Poland

Submission date: 2024-11-26

Acceptance date: 2024-11-26

Online publication date: 2024-11-26

Corresponding author

Tomasz Kiczek

Łukasiewicz Research Network – Poznań Institute of Technology, Poznań University of Technology

Łukasiewicz Research Network – Poznań Institute of Technology, Poznań University of Technology

Journal of Research and Applications in Agricultural Engineering 2024;69(2)

KEYWORDS

TOPICS

ABSTRACT

Onions are one of the most popular cultivated vegetables. In Europe, Poland is a leading producer of this vegetable and a hub where it is peeled and then sent in peeled or chopped form to western EU countries. After the top and root removal process, husks remain that require further manage-ment. It is also crucial to minimise their amount by applying appropriate topping and tailing processes in industrial machines. This is done in order to help prevent food waste and reduce the amount of waste generated. The article presents methods of cleaning onions in terms of cutting off the roots and green parts of the vegetable, focusing on the amount of waste generated in this process. The authors present examples of possible solutions for the cutting process and compare them in terms of the theoretical waste they generate, to identify the method with the greatest raw material savings. Additionally, the article presents the results of theoretical studies on the waste generated by the selected method, considering its various geometric variables.

An analysis of the results is made and conclusions are drawn.

REFERENCES (11)

3.

[3] P. Woźniak, A. Bieńczak, T. Kiczek, and K. Gaszek, “Analiza technologii mechanicznego oczyszczania cebuli w maszynach przemysłowych,” Technika Rolnicza, Ogrodnicza, Leśna, vol. 2, pp. 53–60, 2022.

4.

[4] K. G, T. V, K. G, and K. V, “Studies on Properties of Multiplier CO 4 Onion Bulb (Allium cepa L.var. aggregatum. Don.),” Madras Agricultural Journal, vol. 102, no. March, pp. 84–88, 2015, doi: 10.29321/MAJ.10.001073.

5.

[5] H. Shoba, N. Rajeshwari, and G. Nagaraja, “A Study on Physico-Mechanical Properties of Onion Varieties Under Koppal District, (Karnataka).,” Current Agriculture Research Journal, vol. 5, no. 3, pp. 381–386, Dec. 2017, doi: 10.12944/CARJ.5.3.18.

6.

[6] M. Dabhi and N. Patel, “Mukesh Dabhi, Nagin Patel. Physical and Mechanical Properties of Talaja Red Onion Cultivar,” Bioprocess Engineering, vol. 1, no. 4, pp. 110–114, 2017, doi: 10.11648/j.be.20170104.13.

7.

[7] L. Mieszkalski, “Mathematical modeling of the shape of the onion head saccharic (Allium cepa L.) by the parametric equations,” Postępy Techniki Przetwórstwa Spożywczego, vol. 2, pp. 68–71, 2015.

8.

[8] A. H. Bahnasawy, Z. A. El-Haddad, M. Y. El-Ansary, and H. M. Sorour, “Physical and mechanical properties of some Egyptian onion cultivars,” J Food Eng, vol. 62, no. 3, pp. 255–261, May 2004, doi: 10.1016/S0260-8774(03)00238-3.

9.

[9] B. Devojee, “Studies on engineering properties of multiplier onion,” Agricultural Engineering Today, vol. 45, no. 01, pp. 11–18, Jan. 2021, doi: 10.52151/aet2021451.1529.

10.

[10] P. Woźniak, S. Nosal, and A. Bieńczak, “Analysis of technology and machining devices for cleaning onion in the food industry,” MATEC Web of Conferences, vol. 343, p. 01006, Aug. 2021, doi: 10.1051/matecconf/202134301006.

11.

[11] J. Bohdziewicz and G. Czachor, “The impact of load on deformation progress for ball-shaped vegetables,” Inżynieria Rolnicza, vol. 14, no. 1, pp. 85–91, 2010.

Share

RELATED ARTICLE

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.